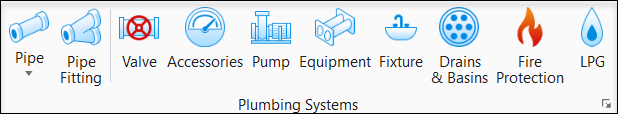

Pipe Fitting

![]() Used to place piping

accessories, include fittings that connect pipe segments in a route.

Used to place piping

accessories, include fittings that connect pipe segments in a route.

Selecting a fitting from the ribbon panel activates the Place Component settings dialog, where you can manage the schema parameters (DG instance properties). Also, the contextual Placement tab appears on the ribbon, that provides placement settings options for the currently selected fitting.

The generic placement settings, along with the unique set of dimensional and data parameters from the datagroup system provide the core workflow used to accurately position mechanical components within a system.

Component categories

Pipe Fitting help completing piping and connecting various plumbing components in a route. Compass to correctly select combinations of elbows, reducers, and traps components to maintain connectivity throughout the route. Technically, a stub-out is a capped off pipe or pipes coming out of the wall or floor that's to be connected to fixtures after the rough-in is trimmed out. Pipe fittings share many of the same properties.

Flanged plumbing fittings fit to the top of the hot water tank allowing all the water to be taken without disturbance to the tank. Flanges of a required pressure ratings are mounted in a route between pressure vessel, tank or between pipe. The cap on the other hand seals the open end of the piping routes. These fittings are easily be placed across the connecting points in the routes and at pipe ends. The connectors are basically flange designs that include weld neck, slip on, blind, gasket, and flex bellows. Flanges fittings share many of the common properties. The pipe caps are conventional cap and the flat cap with dome. Cap fittings share many of the same properties.

Elbows connect pipe routes of different sizes in angles where routes change direction and at connection points where plumbing components are connected in the route. The three elbow tools of plumbing are - the default elbow, bend with heel, and return bend elbow. They share many of the common DataGroup properties.

A coupling connects two pipes to each other. When the size of the pipe is not the same, by setting the required end diameters the fitting may act as reducing coupling or reducer.

Reducer connects pipe routes of different sizes. Reducer transitions are placed using automatic fitting placement functionality as well as individually by manually connecting to existing route elements. Reducer is type of transition where usually there is decrease in size. Reducer geometry is controlled by dimension properties, but also by System Assembly's Offset Option that parametrically sets fitting rise and run characteristics. Pipes use a generic reducer fitting that shares the properties.

Plumbing fixtures including sinks, bathtubs, and toilets are essentially equipped with either an internal or external trap located below or within a plumbing fixture. Trap tools provide U-, S-, or J-shaped pipes. A U-shaped trap is also known as a U-bend. The shape retains a small amount of water after the fixture's use, the water thus prevents sewer gases from entering drain pipes back into the occupied space of the building. The traps types are P-trap, P-trap with heel, S P-trap, and P-trap gully. The specialty of setting radii and angles properties of P-trap gully make it flexible enough to suit the required level of trap. Trap fittings share many of the common DataGroup properties.

Notable Properties

- Connection End Type – The end conditions of fittings are set to flange, male or female connections with full dimensional control by setting the End Type property. Also, the two ends are independent, and may have different connections. For example, the value fl-2;fe-.13 creates a flange at End1 with size 2, and a female connection at End2 with a clearance of .13.

- Angles and Radii – Set the curvature of the p-trap gully at respective ends.

- Convolutions – Sets allowable number of convolutions the bellows sustain the flex.

- Types – The selectable option sets fittings type. The Bush, Nut and Socket types can be set to common types of fittings based on nut, thread, body as a standard practice.

- Ridge Number – The number of ridges in a unit length is set for flexible pipe. Also, the Ridge Distance sets the spacing between the consecutive ridges.

- Standard Angle – Matches standard angle value set by Manufacturer Catalogs.

- Auto Size – The values set in one of these options -Radius or Radius to Diameter Ratio sets other value internally.

Notable Property Options

Manufacturer Catalog – Edits the current Catalog having standard properties assigned to the flange, that had set in the Properties via selecting a catalog name.

Set as Default Auto Fitting Option – Saves the settings from the active pipe, and applies them to pipe tool as defaults.

Radius / Radius to Diameter Ratio – Property options in Auto Size sets the auto size relative to radius or radius to diameter. That is, for Radius Auto Size the Radius to Diameter Ratio follow changes to radius property and vice versa

Offset Option – Opens the Quick Offset dialog where rise and run characteristics of asymmetrical components are generated. Linear and angular offsets in four directions are set by this utility.

The list of fittings available in Pipe Accessory group is compiled in the Pipe Accessory types topic.